As temperatures drop, facility teams start prepping HVAC systems and checking insulation—but there’s one system that often goes overlooked: your backup power batteries. Whether you’re managing a large data center or a small server closet, cold weather directly impacts battery capacity, internal resistance, and overall reliability of your UPS and DC systems.

When your critical infrastructure depends on batteries, understanding how temperature fluctuations affect performance is essential to avoiding downtime.

Cold Weather and Battery Chemistry: What’s Really Happening

Batteries depend on electrochemical reactions to store and deliver energy. As ambient temperatures fall, these chemical reactions slow down—increasing internal resistance and reducing available capacity.

- Lead-acid (VRLA/AGM) batteries lose approximately 20–30% of their rated capacity at 32°F (0°C) compared to standard test conditions at 77°F (25°C).

- Lithium-ion batteries are more efficient at low temperatures but still see 10–20% capacity loss around freezing.

- Below 0°F (–18°C), both chemistries experience sharp performance degradation and longer recharge times.

Even worse: charging batteries when they’re too cold can cause lithium plating or permanent sulfation in VRLA cells, both of which shorten service life.

Real-World Impact

In most regions, winter brings not just lower outdoor temperatures but also dryer air, fluctuating indoor humidity, and uneven HVAC distribution—conditions that can have measurable effects on battery rooms.

- According to IEEE 1188 standards, battery performance decreases roughly 50% for every 18°F (10°C) drop below 77°F.

- A 500 kVA UPS system relying on 192 VRLA batteries could lose the equivalent of up to 40 kWh in available runtime if the battery room temperature drops from 77°F to 50°F.

- Thermal gradients within racks can lead to uneven aging, where outer cells cool faster, increasing internal resistance and creating imbalance across strings.

- Field studies from Schneider Electric show that for every 15°F deviation from optimal temperature, overall battery life expectancy drops by up to 50%.

The data doesn’t lie, the colder temps and temperature fluctuations can damage your batteries and cost your organization more.

Lithium vs. VRLA: Who Handles the Cold Better?

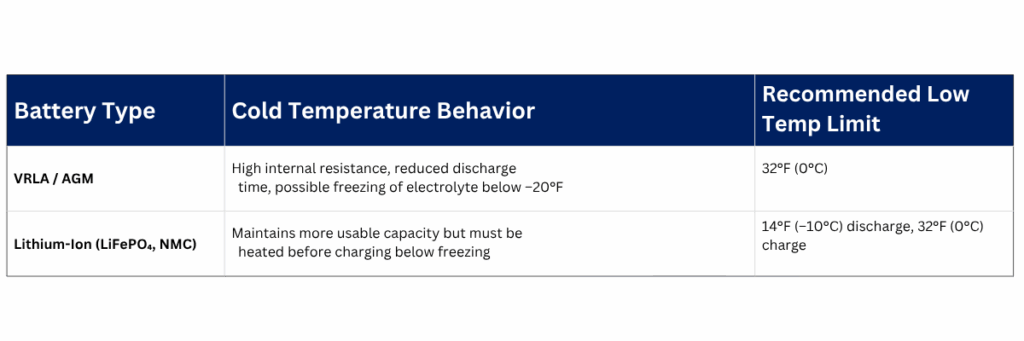

While VRLA (valve-regulated lead-acid) batteries remain common in legacy UPS systems, lithium-ion is increasingly adopted for their high cycle life and thermal stability. But cold weather affects them differently:

Some modern lithium UPS systems integrate battery management systems (BMS) with self-heating features, ensuring reliable operation in colder environments—something traditional VRLA banks can’t match without environmental controls.

Why Cold Weather Failures Happen More Often Than You Think

Data center operators often assume their temperature-controlled rooms are immune to cold-weather effects. But real-world audits tell a different story:

- During winter, intake air for cooling systems can drop room temperatures unevenly—especially near exterior walls or air vents.

- Battery cabinets located on concrete floors without insulation can be 10–15°F cooler than the rest of the room.

- When the ambient temperature dips below 68°F for extended periods, runtime testing results often differ from manufacturer specs, triggering early battery replacement cycles.

Predictive Technology’s field service teams have observed that even in “controlled” rooms, spot temperature variations can swing 5–8°F across a single rack row, enough to cause unequal battery aging across strings.

Protecting Battery Capacity This Winter

Maintain Ambient Temperatures Between 68–77°F (20–25°C)

This is the IEEE-recommended range for VRLA and lithium systems. Temperature stability is more critical than absolute temperature.

Perform Seasonal Battery Testing

Conduct mid-winter discharge or impedance testing to verify available runtime under cold conditions.

Check for HVAC Imbalances

Use temperature sensors at both top and bottom of racks; uneven air flow can drop floor-level temperatures below spec.

Review Your BMS Data Trends

These platforms track temperature, voltage, and impedance in real time—allowing early detection of cells trending out of range.

Avoid Charging in Sub-Freezing Conditions

If your battery room or remote cabinet can fall below 32°F, implement battery warmers or low-temp cutoffs.

Schedule Preventive Maintenance

Cold weather stresses weak batteries—winter is prime time for failures. Testing and equalization charging can prevent unexpected downtime.

Data Drives Resilience

Battery degradation due to temperature swings isn’t just theoretical—it’s measurable. Facilities using Cellwatch and Generex systems report up to 35% longer average battery life when environmental monitoring (like RLE) and temperature alarms are enabled.

By combining predictive analytics with seasonal testing, operators can forecast degradation trends, adjust HVAC loads proactively, and ensure backup systems deliver full runtime—even when outdoor temperatures are near freezing.

Contact Us Today